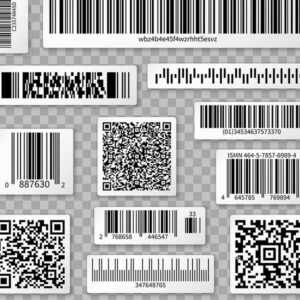

DRG Technologies is a leading durable label manufacturer offering a variety of custom, high-performance labels. Over the last 30 years, we’ve helped hundreds of companies find the perfect label solution for their needs. We’d be honored to help you, too.

Industry-Leading Products from an Experienced Durable Label Manufacturer

DRG Technologies offers a complete portfolio of advanced, high-performance label products to help you meet the most demanding requirements.

Put Our Custom Label Printing and Inventory Management Solutions to Work for You

Supplier Consolidation

Our broad label manufacturing and printing capabilities mean we can replace two or more suppliers — reducing complexity and costs.

Logistics Solutions

As an experienced durable label manufacturer, we have a variety of logistics solutions to help you scale your business and minimize the risk of obsolescence.

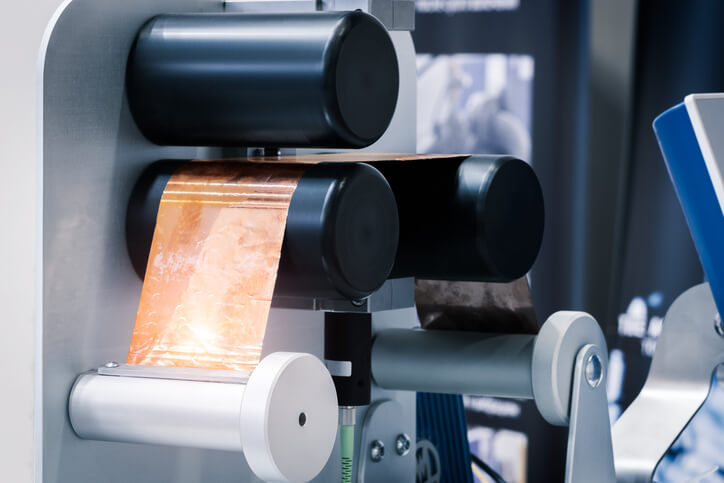

Thermal Print Solutions

Our thermal transfer printing capabilities are a turnkey solution for in-plant custom label printing. We can provide everything you need from start to finish.

Solving Label Manufacturing Challenges for the Following Industries

Get Quick Custom Label Printing for Even the Toughest UL Challenges

With more than 30 years of experience as a durable label manufacturer, we have the expertise and the certifications to help you with demanding label needs. Our facilities are UL-certified, meaning we can help you design, manufacture, and ship high-performance UL labels.

Ready to See What We Can Do for You? Request a Quote Today

Our team is standing by to offer a quote for your next project. As an experienced durable label manufacturer, we offer competitive prices and fast turnaround times.

See the Results We’ve Created for Our Clients

Not sure if DRG Technologies is the durable label manufacturer for you? Learn how we maximize results in our custom label programs for organizations across North America. Explore our case studies, as well as product brochures, tech specs, and more from our valued suppliers like 3M and Avery Dennison.